The Essential Guide to Corrugated Box Dryer Machines: Why They Matter and How They Work

In the world of packaging, efficiency and quality are paramount. For manufacturers of corrugated boxes, maintaining the integrity and strength of their products through various stages of production is crucial. One key component in achieving this is the corrugated box dryer machine. But what exactly is this machine, and why is it so important? In this blog, we’ll dive into the world of corrugated box dryer machines, exploring their function, benefits, and the latest advancements in technology.

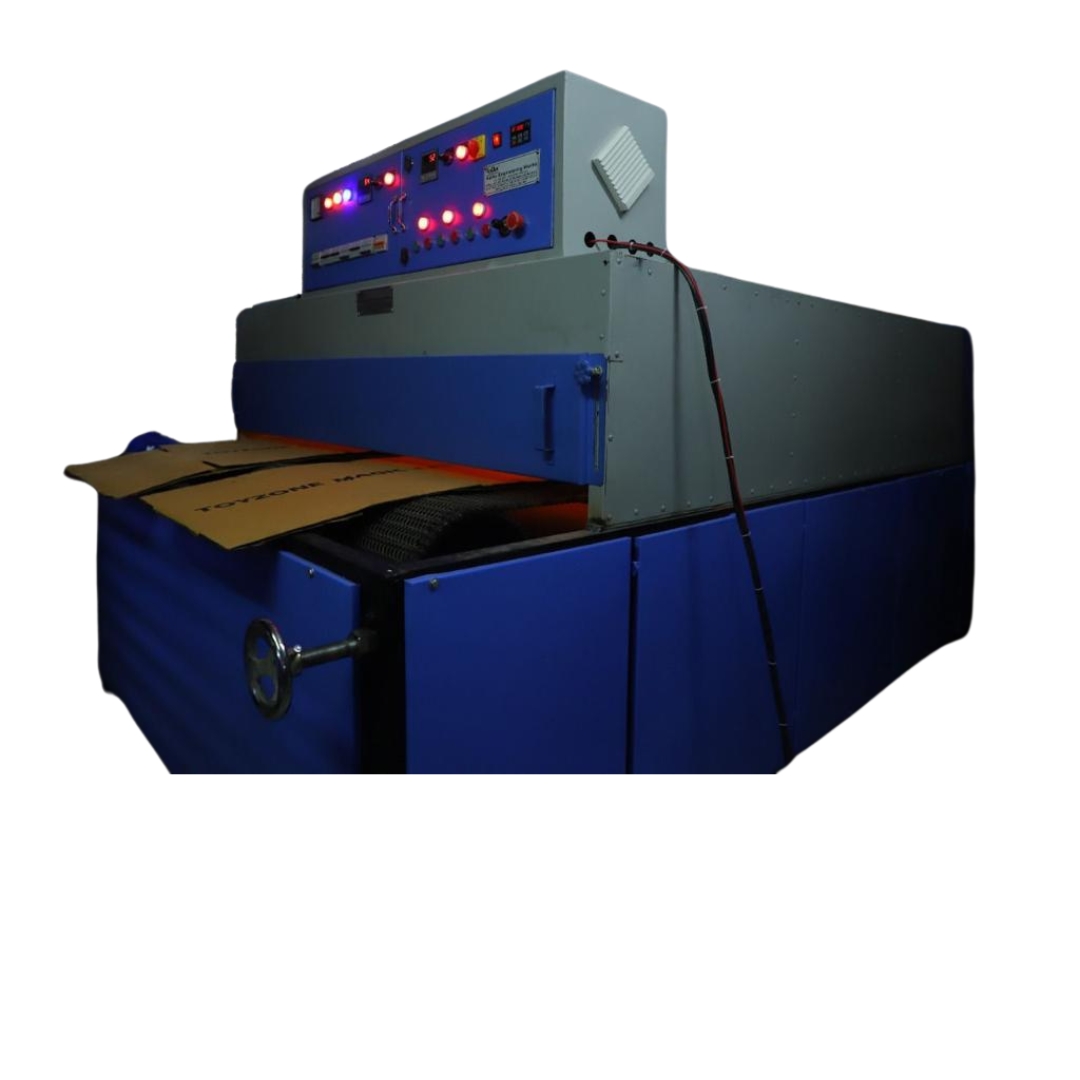

What is a Corrugated Box Dryer Machine?

A corrugated box dryer machine is a specialized piece of equipment used in the production process of corrugated cardboard. Its primary function is to remove moisture from the corrugated paperboard after it has been processed and before it is converted into finished boxes. Moisture removal is a critical step to ensure that the final product has the desired strength and durability.

How Does It Work?

The operation of a corrugated box dryer machine involves several key steps:

- Infeed: The damp corrugated paperboard is fed into the dryer machine. This paperboard has typically gone through the corrugation process, where it has been subjected to moisture and heat.

- Heating: The machine uses either heated air, infrared radiation, or other heat sources to evaporate the moisture. The choice of heating method can vary depending on the machine’s design and the specific needs of the production process.

- Airflow: Efficient airflow is crucial for removing moisture. The machine uses powerful fans or blowers to ensure that hot air circulates evenly across the surface of the paperboard.

- Drying: As the paperboard moves through the dryer, it gradually loses moisture. The drying process is carefully controlled to avoid overheating, which could damage the paperboard or affect its quality.

- Outfeed: Once the paperboard reaches the desired moisture level, it exits the dryer machine, ready to be further processed into corrugated boxes.

Why is Drying So Important?

The drying process is critical for several reasons:

- Strength and Durability: Properly dried corrugated paperboard maintains its structural integrity. Moisture can weaken the paper fibers, leading to reduced strength and potential issues with the finished boxes.

- Print Quality: Moisture can affect the adhesion of ink and other coatings used on the corrugated board. Adequate drying ensures that print quality remains high and consistent.

- Processing Efficiency: Excess moisture can lead to problems in subsequent stages of production, such as die-cutting or folding. Proper drying helps streamline the entire production process.

Benefits of Modern Corrugated Box Dryer Machines

Modern corrugated box dryer machines come with a host of benefits that enhance the efficiency and effectiveness of the drying process:

- Energy Efficiency: Advances in technology have led to the development of energy-efficient dryers that consume less power while maintaining optimal drying performance.

- Precision Control: Many machines now feature advanced controls that allow for precise adjustments in temperature and airflow, ensuring consistent results across different production runs.

- Reduced Downtime: Innovations in design and materials have led to more durable machines that require less maintenance, reducing downtime and improving overall productivity.

- Environmental Considerations: Modern dryers often incorporate features to minimize environmental impact, such as recycling heat or using eco-friendly materials.

Choosing the Right Corrugated Box Dryer Machine

When selecting a corrugated box dryer machine, consider the following factors:

- Production Capacity: Ensure that the machine’s capacity matches your production needs.

- Energy Consumption: Look for energy-efficient models to reduce operating costs.

- Maintenance Requirements: Choose a machine with a reputation for reliability and ease of maintenance.

- Technology Features: Evaluate the technology and control options available to find a machine that offers the best fit for your production process.